In a warehouse’s fast-paced and often dynamic environment, maintaining safety standards is both a priority and a challenge. With heavy machinery, high shelves, and constantly moving inventory, warehouses can be dangerous if proper safety measures are not in place.

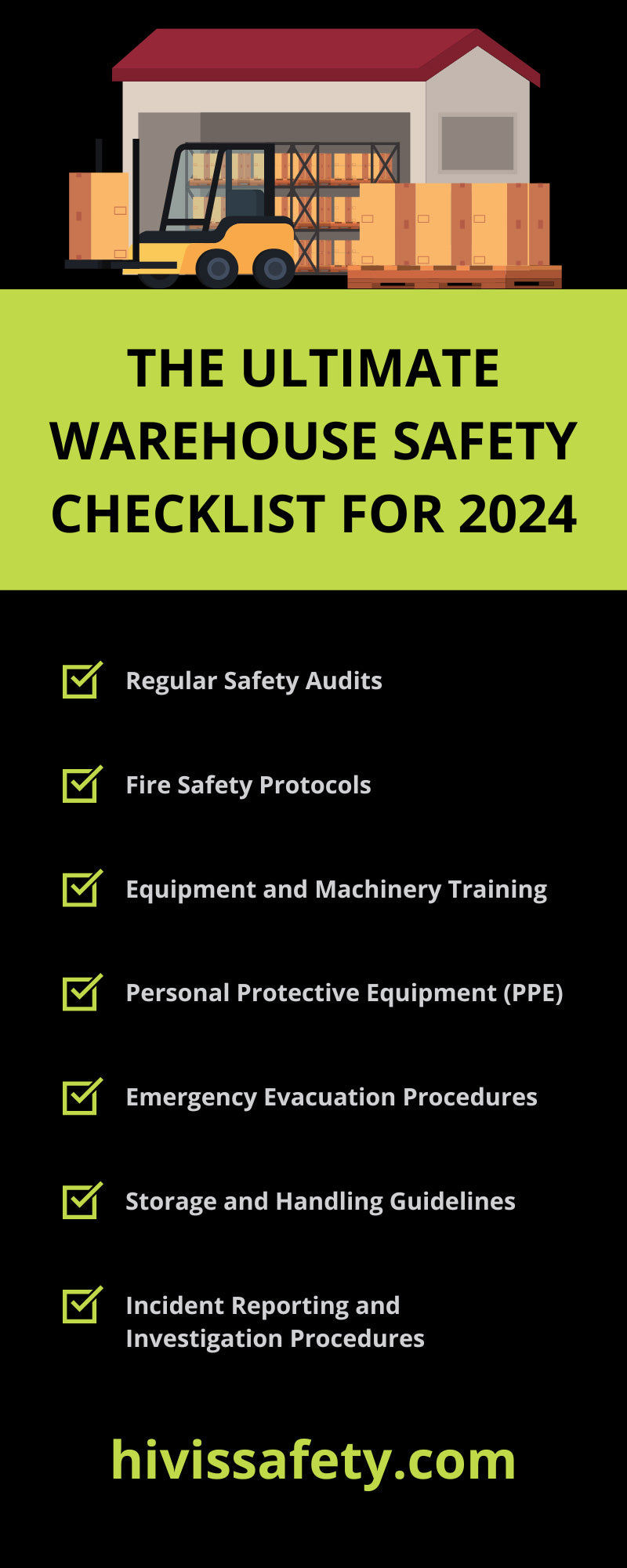

Let’s look at this ultimate warehouse safety checklist for 2024 and ensure that your warehouse is a safe and secure place for both workers and inventory.

Regular Safety Audits

Conducting regular safety audits is the keystone for maintaining warehouse safety standards. These audits should be thorough and systematic, focusing on various aspects such as machinery operation, material storage, aisle and exit accessibility, and fire safety protocols. Businesses can implement corrective actions proactively rather than reactively by identifying potential hazards. When possible, hire individuals with a comprehensive understanding of safety regulations specific to warehousing operations to conduct these audits.

Additionally, engaging employees in the audit process can foster a safety culture, encouraging them to be vigilant and proactive about their environment. Feedback from those on the warehouse floor can be invaluable in spotting risks that may not be apparent during a formal audit. Ultimately, regular safety audits are regulatory compliance exercises and critical investments in the welfare of employees and the efficiency of warehouse operations.

Fire Safety Protocols

Ensuring adherence to fire safety protocols is vital for protecting human and material warehouse assets. These protocols include installing and maintaining fire alarms, sprinklers, and extinguishers throughout the facility and ensuring clear signage for exits and fire equipment. Regular training for employees on how to respond in case of a fire is crucial, including evacuation procedures and the use of firefighting equipment.

It is also important to implement strict controls on smoking and handling flammable materials, as these are common causes of warehouse fires. You should conduct regular inspections to ensure that your layout doesn’t obstruct fire exits and that all safety equipment is in working order. By prioritizing fire safety, warehouses can minimize the risk of fire-related incidents, safeguard personnel and inventory, and ensure the continuity of operations.

Equipment and Machinery Training

Proper training for using equipment and machinery is critical to warehouse safety. Every employee who operates forklifts, pallet jacks, or machinery must receive comprehensive training covering operational procedures, safety protocols, and emergency measures. This training should include initial instruction and ongoing refresher courses to ensure that safety practices are consistently applied and updated according to the latest standards.

Additionally, it’s crucial to establish a system for verifying that only qualified individuals operate machinery and equipment. You can achieve this through licensing systems or regular competency assessments. By investing in thorough training programs, warehouses can significantly reduce the risk of accidents caused by improper use of equipment, thereby creating a safer working environment for all employees. Importantly, this focus on training underscores a commitment to safety that can enhance workplace morale and productivity by showing staff that their well-being is a top priority.

Personal Protective Equipment (PPE)

Ensuring the provision and proper use of Personal Protective Equipment (PPE) is pivotal in enhancing warehouse safety. This PPE includes helmets, safety goggles, gloves, high-visibility clothing, and ear protection, each as a critical barrier against workplace hazards. You should carefully select PPE based on specific risks identified in the warehouse environment, and you must train all employees on its correct usage, maintenance, and storage.

Employers must also enforce PPE usage strictly, monitoring compliance and regularly reviewing PPE policies to adapt to changing safety requirements or introduce new protective technologies. By prioritizing PPE, warehouses can significantly mitigate the risk of injuries, reinforcing a culture of safety that extends beyond mere compliance to embed safety as a fundamental workplace value. This approach protects employees and reduces downtime and the potential financial impact of workplace accidents, thereby supporting overall operational efficiency.

Emergency Evacuation Procedures

Emergency evacuation procedures:

- Are a critical aspect of warehouse safety

- Ensure rapid and organized departure in case of emergencies

- Cover subjects such as chemical spills, natural disasters, and fires

To maximize effectiveness, it’s necessary to clearly document these procedures, regularly update them, and keep them readily accessible to all employees. Regular drills reinforce these procedures, ensuring everyone knows their nearest exits, assembly points, and roles during an evacuation. It is also imperative to designate and train specific employees as emergency wardens who can lead and account for others during an evacuation.

These measures, combined with clear signage for exits and assembly points, can drastically improve the speed and orderliness of an evacuation, significantly reducing the risk of injury. By diligently planning and practicing emergency evacuation procedures, warehouses can safeguard their most valuable assets—their employees.

Storage and Handling Guidelines

Proper storage and handling guidelines are critical for warehouse safety, ensuring that materials are secure and safe to access or move. This storage entails employing the right storage systems, such as pallet racks and shelving units, designed to handle the weight and size of stored items. It’s essential to ensure that all aisles remain clear and unobstructed to prevent accidents and facilitate easy access to materials.

Furthermore, you must train employees on safe lifting techniques and equipment for handling heavy items. Adhering to these guidelines will prevent injuries and enhance the overall efficiency of warehouse operations by maintaining a tidy and organized workspace.

Incident Reporting and Investigation Procedures

Establishing robust incident reporting and investigation procedures is paramount to ensure continuous improvement in warehouse safety. An effective system encourages employees to report every incident, no matter how minor, without fear of retribution. This openness provides a comprehensive understanding of potential hazards and underlying issues, facilitating timely corrective actions. Every report should trigger an investigation to identify root causes and implement preventive measures, thus preventing recurrence.

Additionally, analyzing patterns in reported incidents can highlight areas in need of more focused safety training or procedural revisions. Cultivating a culture that values safety and transparency can significantly reduce workplace accidents and foster a more engaged and knowledgeable workforce.

Ensuring a safe working environment within a warehouse is not just about compliance with regulations; it’s about creating a culture in which you ingrain safety in every action and decision. From conducting regular safety audits to training employees on procedures, each element of this checklist is essential in protecting employees and inventory, enhancing operational productivity, and cultivating a safety-first mindset.

If you need hi-vis clothing, Hi Vis Safety has you covered with our high-quality range of safety apparel. Our commitment to safety and quality is a perfect match for any business looking to prioritize their employees’ well-being and contribute to a safer working environment in the warehouse industry. Contact us today to learn more about our products and services.