It’s essential to ensure you and your staff are using the best possible protective gear when working with hazardous materials. That’s why having a reliable checklist for safety equipment such as work gloves is so important. Meeting OSHA standards helps keep everyone safe from potential harm no matter what industry they may be in.

Let’s explore an essential work gloves checklist to meet OSHA standards and ensure your workplace complies with the proper regulations. Not only will this keep you and your employees safe, but it will also help you save money in the long run.

Why Choose Work Gloves for OSHA Compliance?

Work gloves are an essential part of any workplace safety program. They offer the best protection from contact with sharp objects, hot and cold temperatures, and hazardous materials. OSHA requires that employees be provided with personal protective equipment (PPE) to protect them from possible injury or illness on the job site. Work gloves are one of the most effective types of PPE available and are the best way to meet OSHA standards.

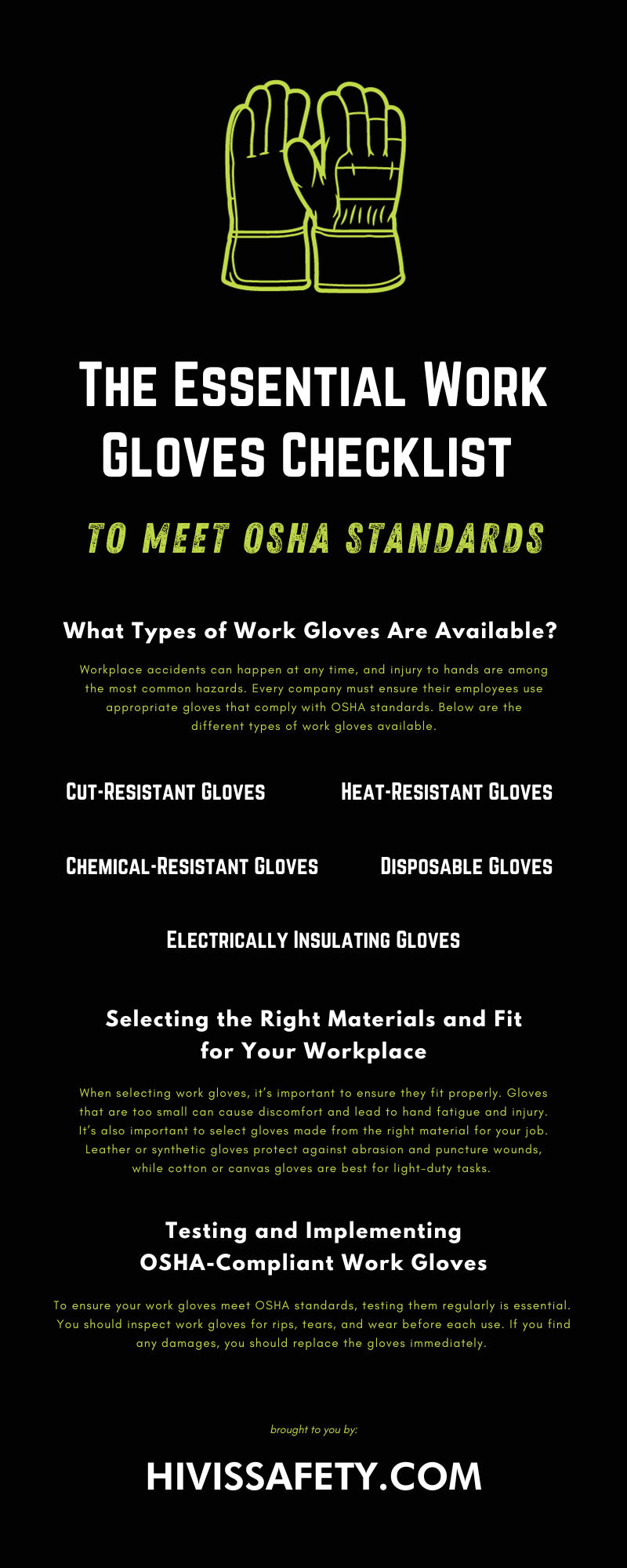

What Types of Work Gloves Are Available?

Workplace accidents can happen at any time, and injury to hands are among the most common hazards. Every company must ensure their employees use appropriate gloves that comply with OSHA standards. Below are the different types of work gloves available.

Cut-Resistant Gloves

Cut-resistant gloves are made of cut-resistant materials such as Kevlar, stainless steel mesh, and high-performance polyethylene fibers. They are designed to protect workers from cuts, lacerations, and punctures. These gloves are best for protecting workers in industries such as construction, metalworking, and automotive manufacturing. Cut-resistant gloves protect the worker during activities such as handling sharp tools, operating machinery with sharp edges, and handling glass or metal objects.

Chemical-Resistant Gloves

Chemical-resistant gloves protect workers from chemicals, oils, and other hazardous materials. These gloves can be made from materials such as neoprene, nitrile, PVC, and latex. Each material has a different resistance level, so selecting the right gloves for the job is essential. Workers in healthcare, agriculture, and manufacturing industries should always use these gloves when handling hazardous chemicals.

Heat-Resistant Gloves

Heat-resistant gloves are designed to protect workers who handle hot or extremely cold objects. Workers in firefighting, welding, and food processing industries require heat-resistant gloves. These gloves are made from different materials, such as Kevlar, neoprene, and leather.

Electrically Insulating Gloves

Workers who handle electrical equipment require electrically insulating gloves. The gloves protect the workers from electric shock and high voltage. These gloves are made from different materials, such as rubber, leather, and neoprene, and offer varying levels of electrical resistance.

Disposable Gloves

Disposable gloves are used in healthcare, food service, and janitorial services. These gloves protect workers from cross-contamination and are designed for single use. Disposable gloves can be made from various materials, such as latex, vinyl, and nitrile. Workers should choose gloves based on their comfort and the level of protection they provide.

Selecting the Right Materials and Fit for Your Workplace

When selecting work gloves, it’s important to ensure they fit properly. Gloves that are too small can cause discomfort and lead to hand fatigue and injury. It’s also important to select gloves made from the right material for your job. Leather or synthetic gloves protect against abrasion and puncture wounds, while cotton or canvas gloves are best for light-duty tasks.

Testing and Implementing OSHA-Compliant Work Gloves

To ensure your work gloves meet OSHA standards, testing them regularly is essential. You should inspect work gloves for rips, tears, and wear before each use. If you find any damages, you should replace the gloves immediately.

You must also create a system for managing and tracking safety equipment and supplies, such as work gloves, to ensure they are always up to date. By implementing an effective tracking system, you can ensure your employees have the right equipment for the job and that it meets all safety standards.

Tips To Ensure Your Work Gloves Last Longer

Maintaining your work gloves is paramount to their longevity and effectiveness. After using the gloves, you should wash them according to the manufacturer’s instructions; harsh detergents can degrade materials, so mild soap is generally preferred. When drying, avoid direct sunlight or high temperatures, which may warp or shrink the gloves. For leather gloves, occasional conditioning helps maintain suppleness and longevity.

Regularly inspect gloves for wear and tear; any holes, tears, or thinning material can compromise protection. If gloves come into contact with chemicals, they should be appropriately cleaned or discarded depending on the nature of the chemical. Be mindful of correct storage—you should keep gloves in a cool, dry place, away from direct sunlight and heat sources. Prolonged exposure to these elements can degrade the material over time.

Lastly, never use gloves beyond their intended lifespan; when in doubt, replace them. The last thing you want in your workplace is unnecessary accidents due to faulty protective equipment.

Troubleshooting Common Problems With Work Gloves

Even the best gloves can suffer from wear and tear over time. Here are some common problems and solutions to help you troubleshoot any issues with your work gloves:

- Rips and tears: Replace the glove immediately if you notice a rip or tear. Make sure your employees inspect their gloves regularly for signs of damage.

- Too tight: Choose a different size or style if the glove is too tight. Select gloves that fit properly to avoid hand fatigue and injury.

- Not enough protection: Choose gloves from the right material for your job. Also, check the labels to make sure they meet OSHA standards.

Work gloves are essential for meeting OSHA standards and keeping employees safe. It’s important to select the right gloves for your job and make sure they fit properly to prevent injury and illness on the job site. Also, create a system for managing and tracking safety equipment and supplies, such as work gloves, to ensure they are always up to date. By taking the right precautions, you can ensure your employees are safe and compliant in any work environment.

If you need anti-vibration gloves or any other protective gloves, Hi Vis Safety is the right place to start. We have a wide range of safety gloves for comfort, protection, and durability. Whether you’re looking for cut- or heat-resistant gloves, our team can help you find the perfect glove for your job. Contact us today to learn more about our selection of work gloves.